Construction, Industry, Mining, Marine - Electric, Air, Hydraulic

Congratulations, you made the perfect saw blade choice.

Work faster:

lowest-wear saw blades in our test!

-

2 x faster cutting time

than most of the blades in our test* -

2 x longer service life than

most of the blades in our test - Same wear than comparable saw blades in our test

-

Best price/performance ratio and application range for our reciprocating saw in the range of tested saw blades

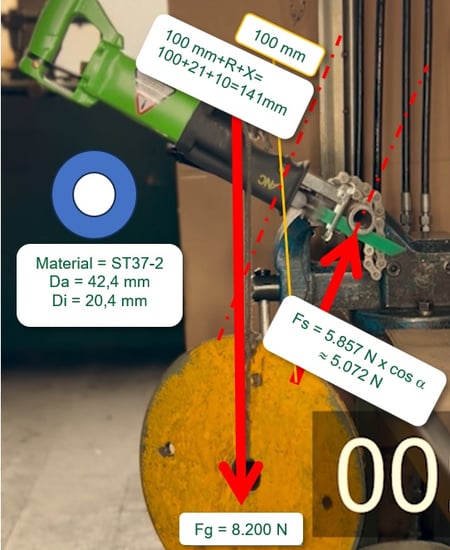

* Standardized test setup, August 2023,

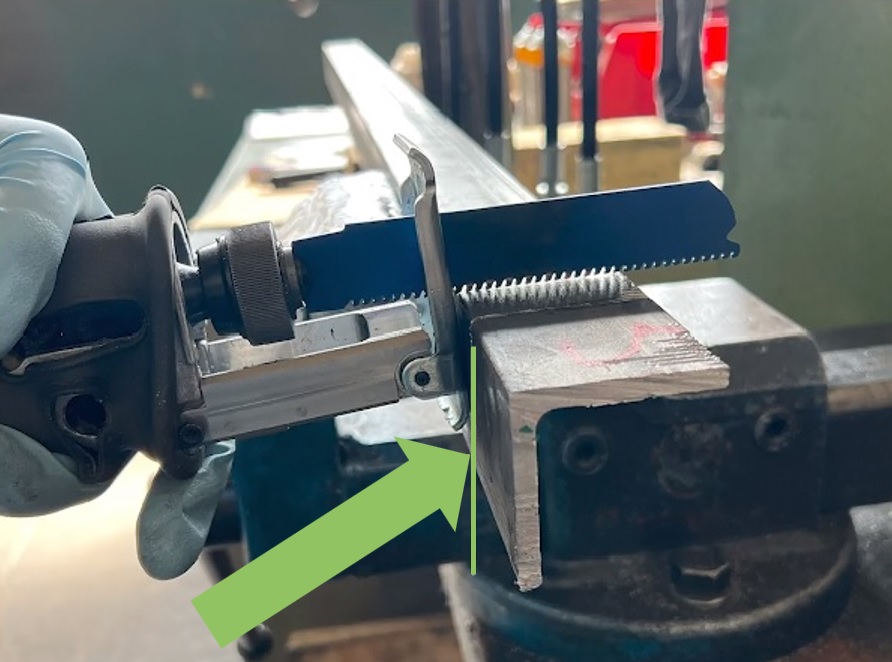

sabre saw on clamping device

*How we tested

-

Standardized test setup

- August 2023

- 5 different saw blades

- Sabre saw fixed on clamping device

- Standardized saw blade material, cutting material, environmental conditions, pressure weight and mounting to ensure a uniform test environment

Twice as fast cutting. Try it out!

The best price/performance ratio & application range for the cheetah reciprocating sabre saw.

Test the 2 high-precision saw blades included in your order exclusively and tell us what you think!

Saw Blades

Technical data & applications

- Material: Hi-Density-Carbide

- Toolholder: Single finger

- Profile: 150x25x1,25 - 8 TPI

Call us now and

re-order quick & easy

- Saw Blades, order number 925 05 0410

- Sabre Saw, order number 512 17 0020

Toll Free: 1-866-305-2198 (USA/Canada)

International: +1-203-587-8257

Hablamos español

Office hours

8:00 am to 5:30 pm EST

All inquiries after business hours will be answered the following business day.

Congratulations on finding the ultimate saw selection!

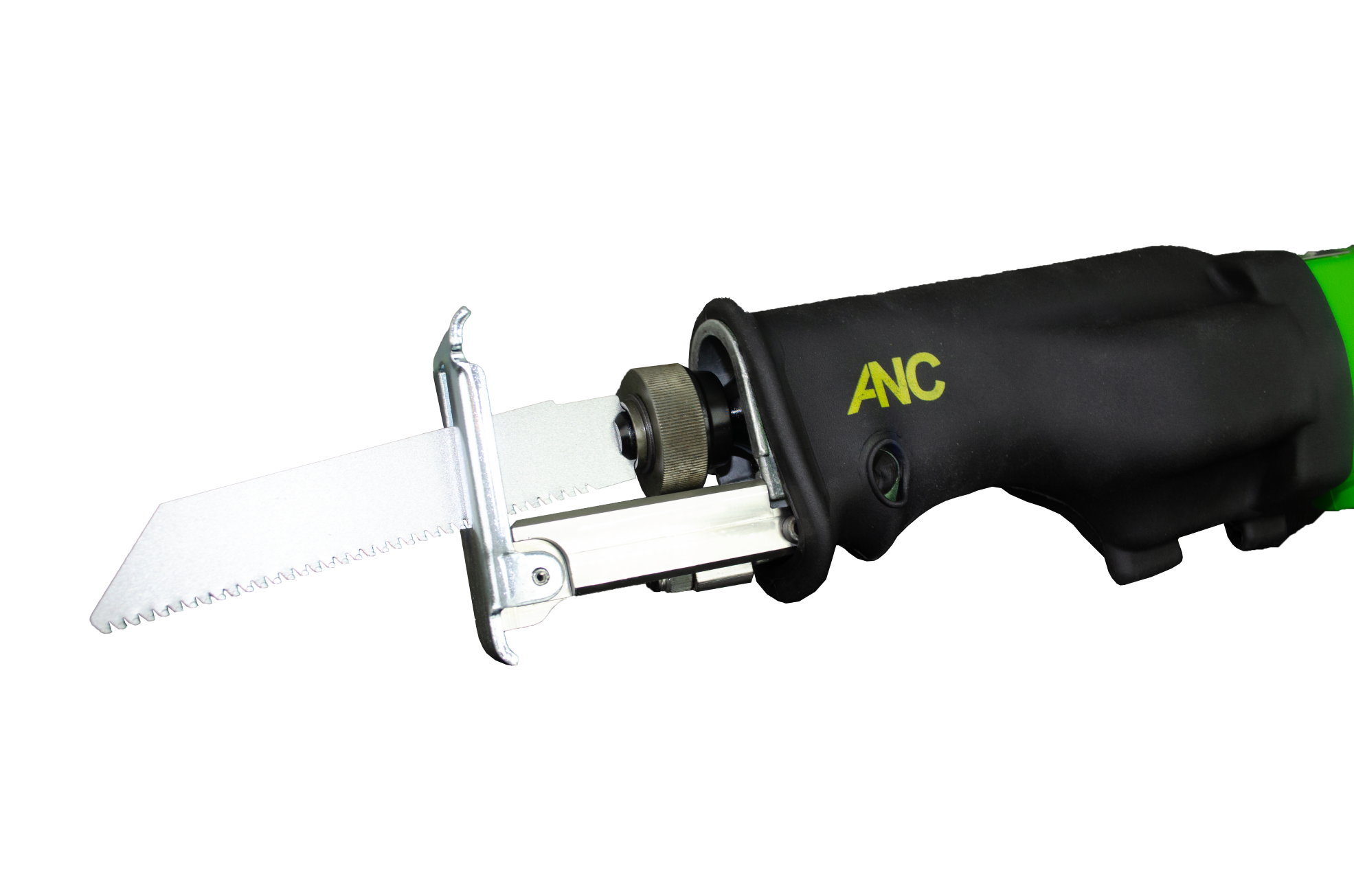

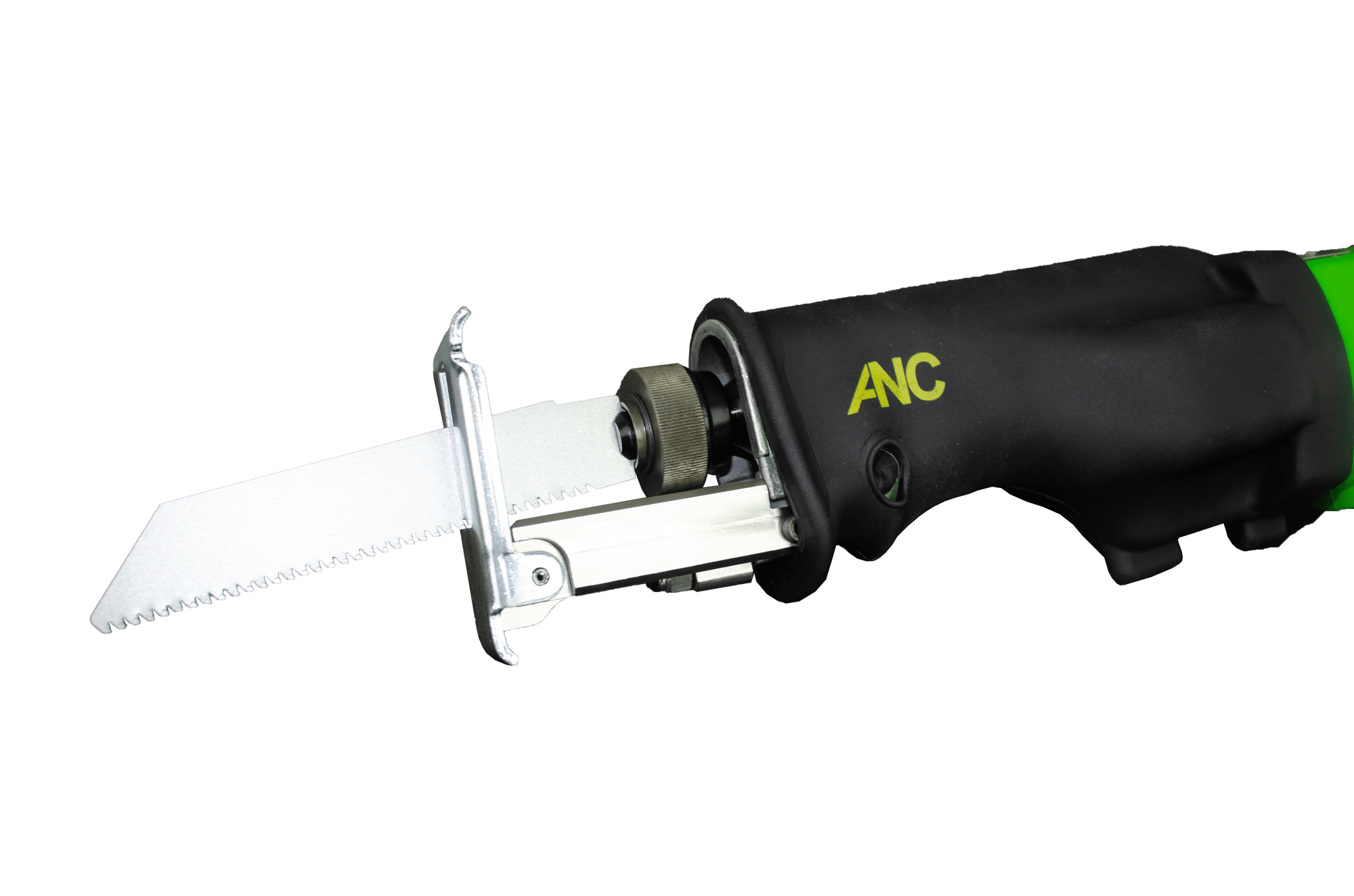

Cheetah saw:

Finish work twice as fast!

Lightweight & handy!

Universal saw suitable in explosion-protected areas for

Plant & Mechanical Engineering · Energy & Pipeline Construction · Metal Industry & Steel Construction · Plastic

Your reciprocating sabre saw is ATEX certified.

Our ATEX certified tools ensure a high level of safety in explosive Atmospheres. To learn more about ATEX certification,

read our ATEX whitepaper.

For more information on our line of ATEX Certified power tools, please call 1-866-305-2198 to speak with one of our technical specialists.

Fatigue-free working: ergonomic handle and handy size · Lean: 9.9 lbs., 4 kg only

Call Us Now

Speak to an Expert

Re-order now!

Call us and speak to our experts

- Saw Blades, type/article number 925 05 0410

- Sabre Saw, type/article number 512 17 0020

Toll Free: 1-866-305-2198 (USA/Canada)

International: +1-203-587-8257

Hablamos español

Office hours

8:00 am to 5:30 pm EST

All inquiries after business hours will be answered the following business day.

The smoother the handling, the easier your work.

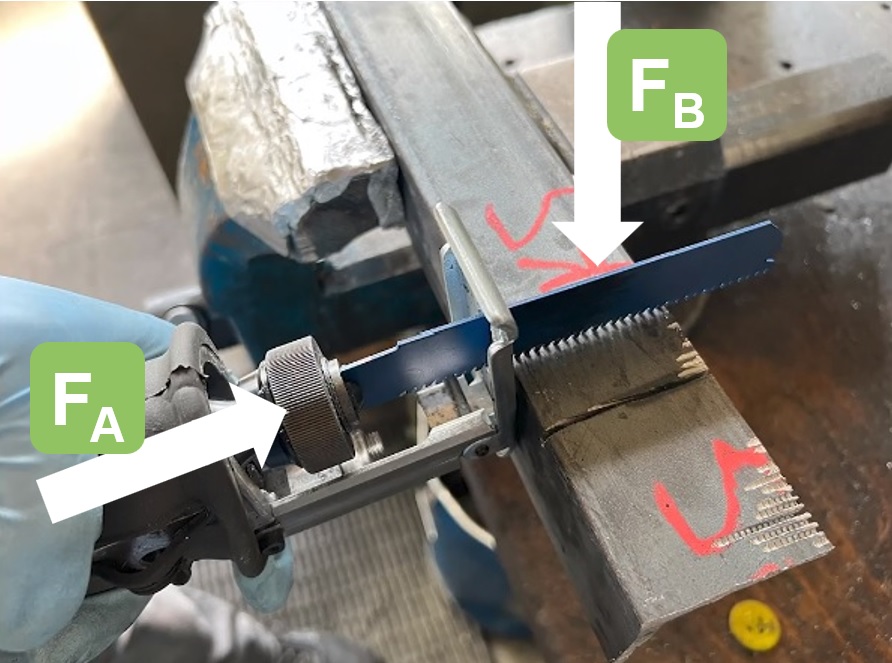

Cutting Position

Choose a secure stance to effectively control the force exerted on the machine or blade when starting the cut.

Saw blade

Select the ideal saw blade based on the material, profile, and hardness of your desired cut.

Alignment

Align the guide shoe with the material and maintain continuous and secure contact throughout the operation.

Contact

Make sure the saw blade stays in constant contact with the material, both while it's being used and when starting up.

Starting-up

Initiate the smooth operation of your machine at a low speed until the saw blade finds its precise path within the cut-sleeve.

Operating force

To achieve optimal cutting results, minimize wear, and maximize performance, carefully monitor and regulate the applied force throughout the operation.

Free lenght (L)

Minimize the free length between the cutting point and the fixed point as much as possible to effectively reduce vibrations.

Control

Handle vertical cuts with caution, avoiding twisting or excessive vertical pressure on the blade. These precautions minimize wear and friction, maximizing efficiency and lifespan of your equipment.

Watch the whole video for perfect handling your Cheetah!

Further information can be found in operating & safety instructions.

Need help? Call us toll-free: 1-866-305-2198 (USA/Canada) · International: +1-203-587-8257

Need accessories &

spare parts?

- Clamping devices for cutting tubes - LINK Jonathan

- Performance Kit: reduce back pressure at air outlet, increase cutting performance (causes increased sound pressure level) - LINK Jonathan

- Maintenance Units - LINK Jonathan

- Hoses - LINK Jonathan

- Transport case - LINK Jonathan

- Multifunction oil - LINK Jonathan

CS Unitec, Inc.

22 Harbor Ave. · Norwalk · CT 06850 · USA · 4330 Center St., Deer Park, TX 77536 USA

Contact us · info@csunitec.com

© CS Unitec, Inc. 2023 - All Rights Reserved